Basics of temperature measurement

The Right Temperature Sensor For Any Measuring Task

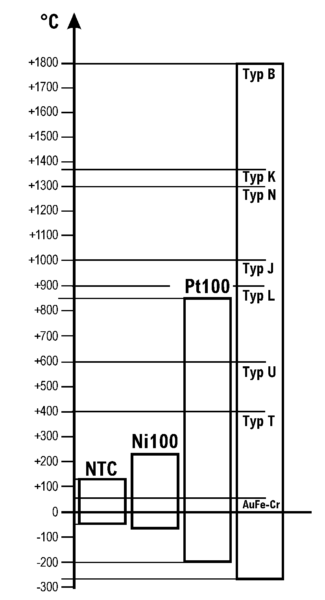

Selecting the right type of temperature sensor depends on your measuring task. For example, thermocouples, resistor-based sensors (Pt100 and Ntc) and pyrometers (infrared sensors) are available.

Rule of Thumb:

- Thermocouples are very fast and provide a large measuring range.

- Resistor-based sensors are more accurate but slower.

- Ntc sensors are very fast, accurate, but they have a limited measuring range.

- Infrared sensors do not contact the device under test and they have very small time constants, but they depend on the emission grade.

- The larger the measuring range, the more universal the possible range of applications.

Selection Criteria:

Select the temperature sensor that suits your measuring task according to the criteria below:

- Measuring range

- Accuracy

- Response time

- Stability

- Type of construction

Thermocouples

Thermocouples

Thermocouples consist of two spot-welded wires of different metals or alloys. The thermoelectric effect at the contact surface is used to measure temperatures. A relatively small thermoelectric voltage is caused, which depends on the temperature difference between the measuring point and the connecting terminals.

Accuracy, Operating Temperatures:

The basic values for the thermoelectric voltages and for the permissible tolerances of thermocouples are specified in standard DIN/IEC 584. Our thermocouple sensors are available in two tolerance classes as per DIN/IEC 584-2.

According to DIN/IEC 584-2, the thermocouple sensors are available in different accuracy classes.

Accuracy classes for the thermocouples type K or type N (extract)

| Class | Range of validity | Limiting deviation (in each case the greater value applies) |

|---|---|---|

| 1 | -40 to 1000°C | ±1.5 K or ±0.004 x | t | K |

| 2 | -40 to 1200°C | ±2.5 K or ±0.0075 x | t | K |

The accuracy class is specified for every thermocouple sensor. The accuracy applies within the above specified range of validity. The operative range is specified for every sensor – depending on its construction. These values refer to the sensor tip. Additionally, the operative ranges of the connecting cable and the transition sleeve (or similar) have to be considered.

The sensor handles and cables are usually resistant to temperatures up to +80 °C. Heat-resistant cables are also available on request. Various types of thermocouples are available; these can be distinguished in terms of their temperature range, sensitivity, and in particular their compatibility with the test substance. The most popular thermocouple is the NiCr-Ni (type K).

Connecting cable with thermal line (stranded wire)

There is no adverse temperature effect at the juncture from measuring element to cable

With immediate effect, the sensor connecting cables for many sensor types will use a new thermal line (stranded wire, thermal line class 2) instead of the conventional compensation line. The transition from measuring element (sensor tip) to connecting cable (in the cable sleeve or in the handle) thus remains, even over a wide temperature span (up to 200 °C), unaffected by temperature error; the usual measuring errors caused by temperature differences at the juncture when using a conventional compensation line can thus with the new thermal line be avoided.

For just a few sensor types and extension cables a compensation line will continue to be used as previously. The compensation lines generally comply with Class 2 as per DIN 43722. For type K the operating temperature range of the compensation line is 0 to 150 °C.

Resistor-Based Sensors (Pt100 Sensors)

Pt100 Sensors

When measuring the temperature the increase in resistance at increasing temperatures is utilised at the Pt100 sensors. The measuring resistor is fed with a constant current and the voltage drop at the resistor is measured as a function of the temperature. Due to the small resistance variation (0.3 to 0.4Ω/°C) the 4-conductor circuit should always be used to exclude any influences from the lead wires.

Accuracy, operating temperatures:

According to DIN/IEC 751, measuring resistors are used for the Pt100 sensors. Several accuracy classes are defined for the Pt100 sensor.

Accuracy classes of the Pt100 sensors (extract)

| Class | Range of validity | Limiting deviation | |

|---|---|---|---|

| wire-wound resistors | film resistor | ||

| B | -196 to +600 °C | -50 to +500 °C | ±(0,3 + 0,005 | t |) K |

| A | -100 to +450 °C | -30 to +300 °C | ±(0,15 + 0,002 | t |) K |

The accuracy class is specified for every Pt100 sensor. Depending on the construction of the sensor, the higher accuracies class A and1/5 DIN class B are available on request. The accuracy applies within in the above specified range of validity. Regarding the accuracy 1/5 DIN class B, the range of validity is sensor specific.

Examples of Pt100 limiting deviations

| Temperature | Limiting deviations | ||

|---|---|---|---|

| DIN class B | DIN class A | 1/5 DIN class B* | |

| 0°C | ±0.3 K | ±0.15 K | ±0.06 K |

| 100°C | ±0.8 K | ±0.35 K | |

| 200°C | ±1.3 K | ±0.55 K | |

| 300°C | ±1.8 K | ±0.75 K | |

| Higher accuracies available at extra cost | order no. OPG2** | order no. OPG5** | |

* Range of validity is sensor specific

** On request, depending on the construction of the sensor

The operative range is specified for every sensor – depending on its construction. These values refer to the sensor tip. Additionally, the operative ranges of the connecting cable and the transition sleeve (or similar) have to be considered. The sensor handles and cables are usually resistant to temperatures up to +80 °C. Heat-resistant cables are available on request.

Measuring ranges, resolution:

PT100 probes FP Axxx are by default assigned measuring range PT100-1 (resolution 0.1 K). Measuring range PT100-2 (resolution 0.01K) can be programmed as alternative on the 1st channel or in addition on the 2nd channel.

Thermistors (NTC Sensors)

NTC-Sensors

NTC sensors (thermistors) have a significantly higher resistance than Pt100 sensors. When measuring temperatures their negative temperature coefficient is utilised, i.e. the resistance is decreasing with increasing temperatures.

Accuracy, operating temperatures:

The accuracy of the sensor element is manufacturer-specific. The sensor element is installed in a sensor and provided with a connecting cable and an ALMEMO® plug. Processing, crossing points, terminal points and connecting cable influence the accuracy of the temperature sensor.

The following accuracy is specified for the NTC temperature sensor with a cable length of 2 meters:

Accuracy of the NTC sensors:

| Range of validity | Limiting deviation |

|---|---|

| -20 to < 0 °C | ±0.4 K |

| 0 to 70 °C | ±0.2 K |

| >70 to 100 °C | ±0.6 K |

The accuracy applies within in the above specified range of validity.

The operative range is specified for every sensor – depending on its construction. These values refer to the sensor tip. Additionally, the operative ranges of the connecting cable and the transition sleeve (or the like) have to be considered.

The handle of the sensor and the cable are heat resistant up to 80 °C.

Types and Fields of Application

The construction variants of temperature sensors are as many and diverse as the measuring tasks.

Tmax is the maximum operating temperature of the sensor tip.

T90 is the time required by the sensor to reach 90% of the step response after a jump in temperature . The specified T90 times refer to measuring operations in a moving liquid. The temperature sensors listed are also available, on request, with other lengths and diameters

Surface sensors with flat measuring tip - For measurements on good heat conductors, on even and plain surfaces.

Surface sensor with spring-type thermocouple band - For quick measurements, also on non-plain surfaces.

Immersion probes - For measurements in liquids, as well as powdery substances, air and gases.

Sensors with heat-resistant measuring tip - For measurements at extremely high temperatures.

Sensor with penetrating tip - For measurements in plastic and pasty substances.

Sword probe - For measurements in paper, cardboard and textile stacks.

Transducer with free sensor - For measurements in air and gases

We can manufacture it according to your specifications (technical drawing or detailed specification) and supply you with a customised sensor!

ALMEMO® temperature measurement

ALMEMO® temperature measurement

Every ALMEMO® sensor can be adjusted, i.e. correction values of the sensor can be stored in the connector.

Thus, the measuring accuracy can be significantly increased.

During DAkkS/DKD or factory calibrations performed by the Ahlborn Company, the correction values are recorded, stored in the sensor plug and locked. The adjustment can be realized in 2 points (zero, gradient) or in over 30 points as multi-point adjustment. Thanks to this procedure the slightest deviations are archived on the calibrated temperature points.

The multi-point adjustment is described in detail in chapter “Input connectors” and in chapter “Calibration certificates”.

Precise temperature measurement thanks to digital ALMEMO® sensors

Digital ALMEMO® sensors are used to measure temperatures with high precision.

Any Pt100 and NTC sensor can become a digital sensor with the appropriate ALMEMO® measurement plug.

For Pt100 sensors, the digital ALMEMO® D7 measurement plug is used in combination with an ALMEMO® D7 measuring instrument. For NTC sensors, the digital ALMEMO® D6 measurement plug is used in combination with any current ALMEMO® measuring device.

The overall accuracy is determined only by the temperature sensor with the connected ALMEMO® measurement plug, independent from the ALMEMO® display device / data logger. The complete measuring chain, consisting of temperature sensor and the connected ALMEMO® measurement plug can be calibrated. An increased accuracy can be achieved by a multi-point adjustment of the sensor during the calibration process.

Temperature sensor Pt100 with digital ALMEMO® D7 measurement plug

High resolution 0.01 K within the complete measuring range up to 850°C.

Linearization of the Pt100 characteristic with accurate calculation method.

Increased accuracy for calibrated sensors thanks to multi-point adjustment of the Pt100 sensor.

The digital ALMEMO® D7 measurement plug works with an own, integrated A/D converter. The high resolution of 0.01 K can be achieved within the complete measuring range going up to 850°C. The linearization of the Pt100 characteristic is calculated accurately according to DIN IEC 751 (no approximation procedure).

To designate a sensor it is possible to program comments with up to 20 characters in the ALMEMO® D7 measurement plug

For technical data regarding the ALMEMO® D7 measurement plug Pt100 ZPD700FS, see chapter “Input connectors”.

Temperature sensor NTC with digital ALMENO® D6 measurement plug

High precision. High resolution 0.001K within the measuring range of -20 to +65°C.

Linearization of the NTC characteristic according to Galway Steinhart with accurate calculation method.

Increased accuracy thanks to multi-point adjustment of the NTC sensor during the calibration process.

The digital ALMEMO® D6 measurement plug works with an own, integrated A/D converter. The linearization of the NTC characteristic is calculated accurately with the Galway Steinhart coefficient (no approximation procedure). For the measuring range of -20 to +65°C, a high resolution of 0.001 K can be achieved. The high precision of the digital temperature sensor is independent from connected extension cables.

For technical data regarding the ALMEMO® D6 measurement plug, see chapter “Input connectors”.