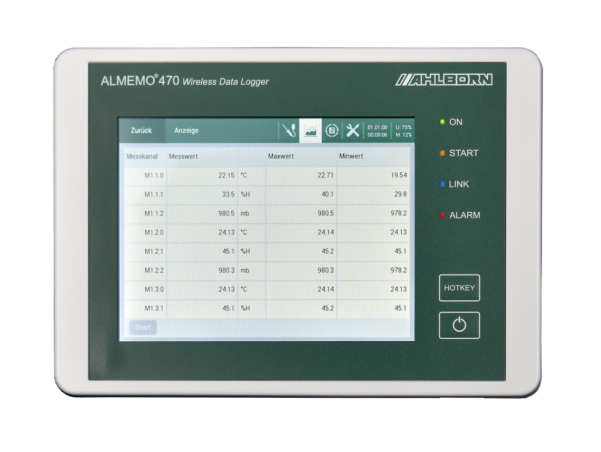

In the pharmaceutical industry and medical technology, process or data mapping has become an important component in the approval process. Also the recording of measured values during room monitoring and simple measurements on a product are more in demand than ever. This kind of documentation or process optimization is nothing unusual for ALMEMO® measurement technology. The product portfolio includes fully digital sensors that can also be connected via the wireless data logger system ALMEMO® 470. Especially the wireless logger system stands out due to its simple network topology. The special feature of the radio system is the radio sensor, which automatically serves as a repeater as soon as the central logger has lost the measuring point due to distance problems or signal weakness.

Even wired solutions are still in great demand. The ALMEMO® D6 and D7 systems are becoming more and more popular. These full digital sensors allow the user, as is usual with the ALMEMO® System, not only the flexible exchange of sensors but also the very simple re-calibration of sensors without removing the complete hardware. Complete system solutionsfollowing the example of Industry 4.0 are more and more implemented in measurement applications. The digital ALMEMO® measurement technology with its unique possibilities is trend-setting here.

Please ask us